🌟 Introduction: A Rapidly Growing Industry

As Australia accelerates its shift toward electric mobility, one question is becoming increasingly important: What happens to EV batteries once they reach the end of their life?

With EV adoption rising and governments committing to sustainability targets, EV battery recycling companies in Australia are stepping up to build a circular energy economy. These companies recover valuable minerals like lithium, cobalt, and nickel—reducing environmental impact and creating new job opportunities across the clean-energy sector.

🔍 Understanding How EV Battery Recycling Works

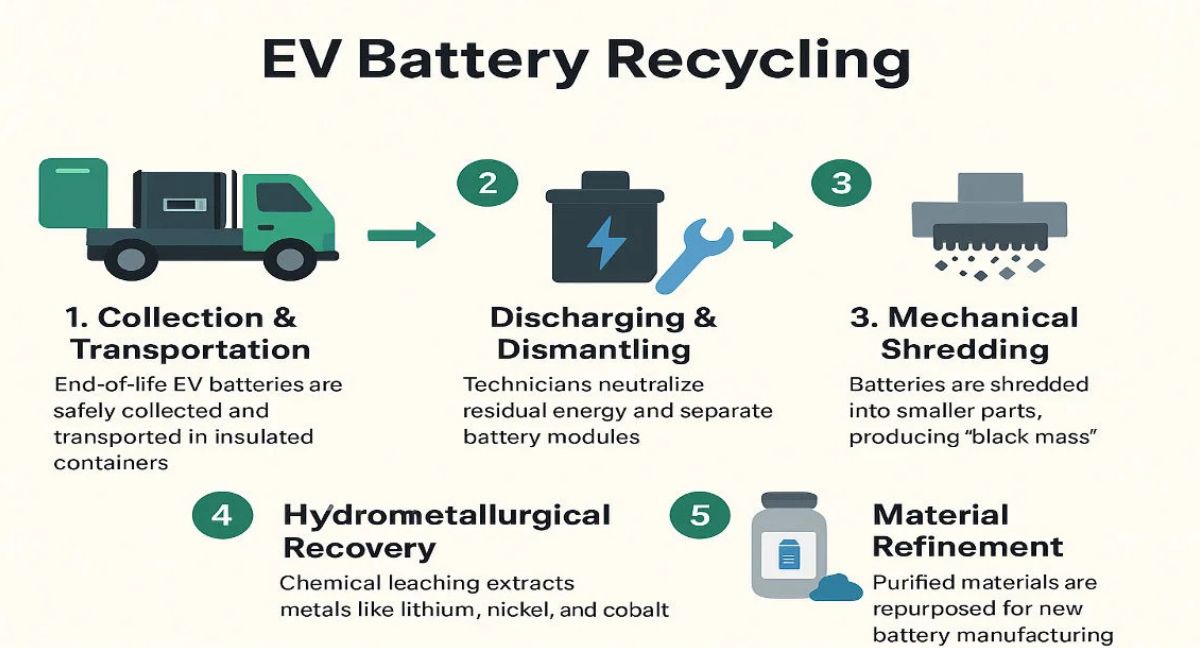

EV battery recycling is a highly technical process designed to safely extract and reuse critical minerals. The goal is to keep valuable materials in circulation while minimizing waste.

Table: Key Stages of EV Battery Recycling

| Stage | Process | Description |

|---|---|---|

| 1 | Collection & Transport | Batteries are safely removed from EVs and shipped to licensed facilities. |

| 2 | Discharging & Dismantling | Remaining energy is neutralized; packs are broken down into modules. |

| 3 | Mechanical Shredding | Packs are shredded to produce “black mass” containing useful metals. |

| 4 | Hydrometallurgical Recovery | Metals such as lithium and cobalt are chemically extracted. |

| 5 | Refining | Purified materials are prepared for new battery production. |

This sector is growing rapidly thanks to government backing and Australia’s goal of becoming a leader in circular battery technologies.

🇦🇺 Australia’s Policy and Market Landscape

Australia is investing heavily in battery recycling to support its clean-energy transition.

Government Programs Supporting Battery Circularity

| Initiative | Description |

|---|---|

| B-Cycle Stewardship Scheme | A national program for safe battery collection and recycling. |

| Circular Economy Infrastructure Fund | Funds new recycling and processing plants. |

| Critical Minerals Strategy 2024 | Positions Australia as a leader in refining and recycling lithium and nickel. |

By 2030, Australia could generate over 30,000 tonnes of used EV batteries—creating a major opportunity for recycling companies and clean-tech professionals.

🏭 Top EV Battery Recycling Companies in Australia (2025)

Below is a breakdown of leading recycling companies reshaping the battery industry.

1️⃣ Lithium Australia Limited (Envirostream)

Location: Melbourne, VIC

Envirostream, a subsidiary of Lithium Australia, is the country’s first commercial-scale EV battery recycling operator.

Key Highlights

-

Operates Australia’s first EV battery processing plant

-

Recovers up to 95% of metals

-

Partnerships with BYD Australia and other OEMs

-

Uses advanced mechanical + hydrometallurgical technologies

Quick Overview Table

| Metric | Value |

|---|---|

| Head Office | Melbourne |

| Processing Capacity | 3,000+ tonnes/year |

| Recovery Efficiency | Up to 95% |

| Partners | BYD, LG, Tesla (research) |

2️⃣ EcoBatt (Ecocycle Group)

Location: Campbellfield, VIC

EcoBatt is known for one of the most technologically advanced battery recycling facilities in Australia.

Key Highlights

-

First “Battery-in-Device Shredding” plant

-

Supported by the Circular Economy Victoria Fund

-

Handles EV batteries and energy-storage systems

-

High-efficiency mechanical recycling and fire-safe processes

Overview Table

| Aspect | Details |

|---|---|

| Specialty | EV & Stationary Storage Batteries |

| Annual Capacity (Target) | 30,000 tonnes |

| Technology | BIDS + Hydrometallurgy |

| Notable Support | Government of Victoria |

3️⃣ Infinitev (Reuse & Second-Life Battery Solutions)

Location: Melbourne, VIC

Infinitev takes a unique approach by repurposing EV batteries into second-life energy storage units before recycling them.

Key Highlights

-

Converts EV battery modules into home/business storage

-

Certified testing for safe second-life applications

-

Works with dealers for battery take-back programs

Company Snapshot

| Feature | Information |

|---|---|

| Founded | 2018 |

| Focus | Reuse → Repurpose → Recycle |

| Headquarters | Melbourne |

| Specialty | Second-life storage solutions |

4️⃣ ReSource Technology

Location: Perth, WA

ReSource Technology focuses on refining black mass and recovering battery-grade chemicals.

Key Highlights

-

Strong in hydrometallurgical refining

-

Strategic location near mining and export hubs

-

University research partnerships advancing solvent extraction technologies

| Feature | Details |

|---|---|

| Location | Perth |

| Annual Capacity | ~5,000 tonnes |

| Technology | Hydrometallurgy |

| University Partner | Curtin University |

🔬 Technology Driving Australia’s Battery Recycling Boom

| Technology | Description | Examples |

|---|---|---|

| Mechanical Separation | Shredding, sorting, sieving to extract metals | EcoBatt, Envirostream |

| Hydrometallurgy | Liquid chemical recovery of lithium, nickel, cobalt | ReSource, Envirostream |

| Pyrometallurgy | High-temperature metal extraction | Under development |

| Direct Recycling | Refurbishing materials without breaking chemical structure | CSIRO research |

CSIRO is pioneering methods that could recover up to 98% of battery materials in the coming years.

📈 Market Trends & Future Outlook

Australia’s recycling capacity is expanding due to the growing volume of EVs, renewable storage systems, and global demand for critical minerals.

Key Market Drivers

| Driver | Impact |

|---|---|

| EV Sales Growth | More battery waste and recycling demand |

| OEM Partnerships | Long-term contracts for recyclers |

| Policy Support | Encourages investment in recycling plants |

| Mineral Demand | Boosts value of recovered metals |

🌱 Environmental & Economic Benefits

Recycling EV batteries supports Australia’s sustainability and economic growth goals.

Benefits

-

Reduces dependency on mining

-

Lowers carbon emissions compared to raw mineral extraction

-

Generates skilled job opportunities

-

Strengthens local supply of critical minerals

-

Supports domestic battery manufacturing

⚙️ Industry Challenges

| Challenge | Explanation |

|---|---|

| Low initial return volumes | EVs are still relatively new in Australia |

| Transportation risks | Lithium batteries require careful handling |

| Economic uncertainty | Metal prices influence profitability |

| Emerging chemistries | LFP batteries require alternative recycling methods |

These challenges are expected to ease as EV adoption grows and regulations strengthen.

🚗 Automaker Partnerships Fueling Growth

Automakers are collaborating with local recyclers:

-

BYD Australia → Partnered with Lithium Australia

-

BMW Group Australia → In-house recycling pilot

-

Tesla → Sends returned batteries to approved recyclers

-

Hyundai Australia → Exploring second-life storage projects

🧩 Comparison Table: Leading Recycling Companies

| Company | Location | Key Focus | Annual Capacity | Technology | Partnerships |

|---|---|---|---|---|---|

| Envirostream | Melbourne | EV Packs | 3,000 t | Mechanical + Hydro | BYD, LG |

| EcoBatt | Campbellfield | All Li-ion Types | 30,000 t (target) | BIDS + Hydro | Govt of Victoria |

| Infinitev | Melbourne | Second-Life Use | N/A | Testing + Refurbishment | Dealerships |

| ReSource Technology | Perth | Black Mass Refining | 5,000 t | Hydrometallurgy | Curtin University |

🔮 Future Outlook: Australia as a Circular Battery Leader

By 2035, Australia is expected to operate a fully developed EV battery recycling ecosystem with:

-

Nationwide collection systems

-

Advanced refining plants

-

Local battery manufacturing using recycled materials

-

Export opportunities for refined battery chemicals

This shift positions Australia not only as a leader in lithium extraction—but as a global hub for sustainable circular energy solutions.

1 thought on “EV Battery Recycling Companies in Australia”